Do you see your plant constantly on a breakdown as a result of a motor failure? Are you forced to spend a vast amount of time replacing electrical motors that are essential to the productivity of your plant?

Is there a device that can reduce downtime whilst increasing the lifespan of your electrical motor?

In this NEW series, we discuss Variable Speed Drives as an essential component to increase the lifespan of your electrical motors and reduce maintenance-associated downtime.

In part 1, we give you an overview of VSD’s – what they are, their benefits and the protection they offer to a motor.

Watch this space to catch the full series!

What are Variable Speed Drives?

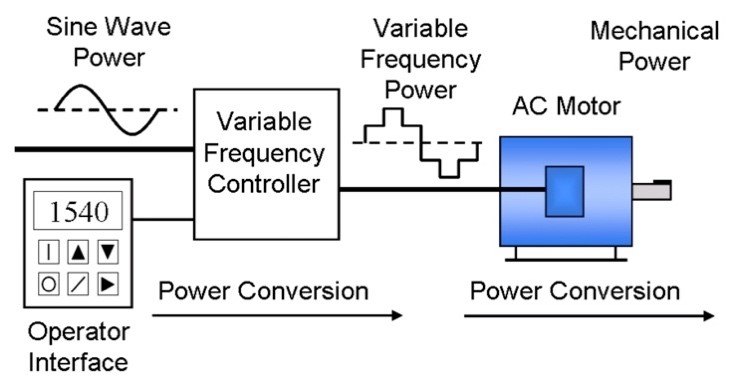

A Variable Speed Drive (VSD) or Variable Frequency Drive (VFD) is a controller that is used to drive an electric motor. It does this by converting the frequency of the supply electricity into a variable frequency output. The variation in frequency enables the drive to control the operation of the motor. A low frequency will cause the motor to operate at a low speed, whilst a higher frequency enables it to operate at a faster speed.

The diagram below depicts the basic principle of operation of a VSD.

How is the Frequency and Speed related in an Asynchronous Motor?

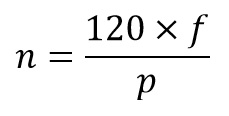

The synchronous speed of an electrical induction motor is determined by:

- The frequency of the supply

- The number of poles in the motor

It can be calculated using the following equation:

Where:

n = shaft rotation speed (rpm)

f = frequency of electrical power supply

p = number of poles

What are the Key Benefits of Using a VSD?

- Energy costs can be reduced

If an application requires a motor to not run at full speed, then a VSD can be used to match the speed of the motor driven equipment to the load requirement.

- Increase Production Using Stricter Process Control Measures

Operating a motor at the most efficient speed for the application will cause fewer mistakes to occur resulting in production and profit levels increasing.

- Extension of Equipment Life and Reduction in Maintenance

Equipment will last longer and will have less downtime due to maintenance when the motor is controlled using a VSD. Due to the VSD controlling the frequency and voltage.

Optimizing motor control systems using VSD’s can reduce energy consumption in your plant by as much as 70%.

What Protection does a VSD Provide to a Motor?

A VSD provides the following complex protection mechanisms to a motor:

- Stall prevention

- Current limitation & overcurrent protection

- Short Circuit Protection

- Under-voltage and Overvoltage Protection

- Ground Fault Protection

- Power supply phase failure protection

- Motor thermal protection through sensing of the motor winding temperature.

In part two of the series, we answer the question “How does a VSD work?” We also mention the various types of VSD’s and the protection of VSD’s. The series ends with sizing VSD’s and a comparison of VSD’s with soft starters. Stay tuned to catch the full series!

Need advice on the best VSD for your specific application? CHAT to our experts now!