High magnitude abnormal currents could be a result of various faults that may occur at your facility. These lead to the unnecessary replacement of equipment and electrical wiring - a costly affair, especially if it causes production downtime…. Is there protection that will prevent this from happening in your facility?

In this NEW series, we will be taking you through the ins and outs of circuit breaker technology. In part one of the series, we give you an understanding of what circuit breakers are, how they work and how they compare to fuses.

What is a Circuit Breaker?

A circuit breaker is an electrical switch designed to protect an electrical circuit from damage caused by overcurrent/overload or short circuit. Its basic function is to interrupt current flow after protective relays detect a fault.

How does a Circuit Breaker Work?

All circuit breakers consist of fixed and moving contacts. These contacts are in contact with each other in normal current carrying conditions. The contacts are engaged with each other by the pressure of a spring when the circuit breaker is closed.

The live wire is wound around the magnet to create a solenoid (electromagnet). The number of turns around the magnet is calculated based on the specified fault current rating. Load current passes through the electromagnet coils so the electromagnet responds to short-circuit currents. A high-level of current thus makes the electromagnet generate enough field strength to attract a nearby iron (contact). As the contact moves toward the electromagnet, the contact rotates the trip bar to trip the breaker, open the current path, and de-energize the electromagnet coils.

In normal operating conditions, the circuit breaker arms can either be opened or closed for switching and the maintenance of the electrical system. A circuit breaker can be opened by applying pressure to a trigger.

If a fault has to occur, the solenoid is energized resulting in the contacts being separated, thus opening the circuit.

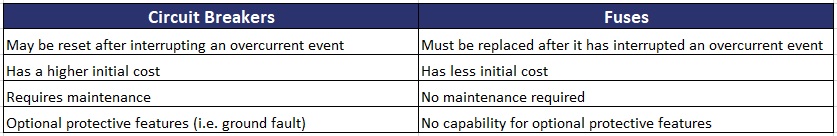

What are the main differences between circuit breakers and fuses?

Common overcurrent protection devices (OCPDs) include circuit breakers and fuses. While the purpose of the fuses and circuit breakers is the same, there are fundamental differences, which are important to understand when making selections for protection of equipment and personnel.

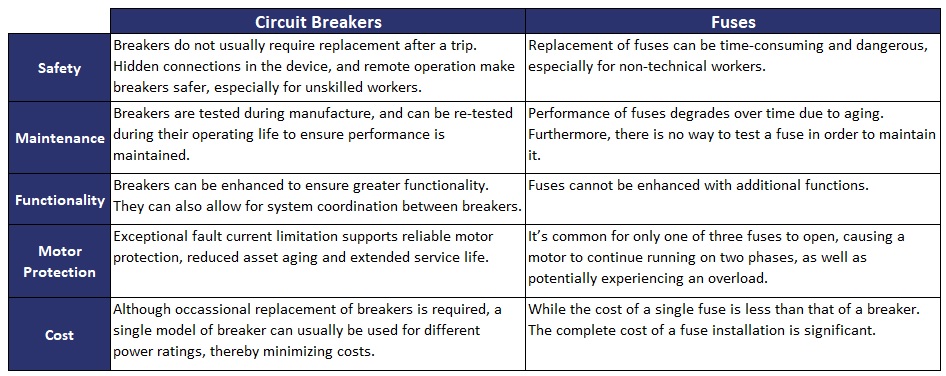

Why should you choose circuit breakers over fuses?

Motor protection is essential to maintaining productivity in processing and manufacturing operations. Typically, the lower cost of fuses often resulted in them being chosen over circuit breakers for this application. However, with the evolution of breakers over the years, we are seeing breakers being used more widely than fuses. Comparing modern circuit breakers to fuses reveals how circuit breakers can help machine manufacturers and facility management teams achieve greater safety and reliability, lower costs, and support for energy management initiatives. Here are 5 reasons why circuit breakers should be chosen over fuses:

1. Enhanced safety and reduced downtime

One of the reported causes of fires in industrial environments is a fuse that has been replaced with the wrong model or rating, or even with wires or paper clips. These kinds of mistakes are avoided with circuit breakers, as they usually do not require replacement after a trip. Additionally, replacing fuses takes more time than simply reclosing a breaker. This means circuit breakers help minimize downtime and production losses.

2. Consistent performance

One downside of fuses is that their performance can degrade due to aging, even causing them to open during normal conditions. In addition, there is no way to test a fuse, so you will never know the exact current value that will cause it to open. In contrast, circuit breakers are tested during manufacture and can also be retested during their operating life to ensure performance is maintained.

3. Optimal functionality

Unlike fuses, circuit breakers can be enhanced with additional functions, such as ground fault protection. They also allow for system coordination between breakers (e.g. selectivity, cascading). The newest, most advanced circuit breakers offer a large breadth of capabilities in a compact size with flexible designs that enable field-upgrading. Add-ons can include remote control and status indication, alarm and auxiliary contacts, power and energy measurements, and network communications.

4. Extended protection

The breaking capacity of a circuit breaker can be greater than equivalent fuses (up to 150 kA). And under overload conditions, a circuit breaker can trip up to 1000 times faster than a fuse. Some circuit breakers also provide exceptional fault current limitation, a capability previously associated only with fuses. This not only supports reliable protection, it also reduces asset aging and extends service life. Another aspect of protection to keep in mind is that it’s common for only one of three fuses to open, causing a motor to continue running on two phases, as well as potentially experiencing an overload. This will never happen with a circuit breaker, which will always break all three phases simultaneously.

5. Cost savings

While the cost of a single fuse may be less than that of a breaker, the cost of a complete fuse installation is more significant. This is because three fuses are required for a three-phase circuit, each requiring a fuse base. Fuses do not have built-in switching capability so the addition of an upstream switch is required. Furthermore, fuses require larger enclosures, due to their heat dissipation. Lastly, when one fuse opens, all three should be replaced. Thus, in total, the complete cost of using fuses can be greater than a circuit breaker.

Watch this space

In the second instalment of the series, we go into detail about the various components of a circuit breaker. Watch this space to learn more!

Are you experiencing regular downtime, or perhaps you’re looking at measures to ensure cost savings in your production? Chat to one of our electrical experts, we’ll recommend solutions to ensure your facility runs smoothly!