We’re wrapping up our series on Circuit Breakers by taking a look at:

1. The common reasons why an industrial circuit breaker might trip

2. How to size a circuit breaker

Missed out on previous articles in this series? Click below to catch up now!

Part One - Circuit breaker basics and how they compare to fuses

Part Two - Circuit breaker components

Part Three - Types of circuit breakers

Common reasons why Circuit Breakers Trip

A circuit breaker that trips regularly is annoying – but this actually indicates that the breaker is doing its job properly, which is to cut off the electric supply when an excessive current is detected in the circuit. Refer to Part One in this series to learn more about how circuit breakers work.

Why would an industrial circuit breaker trip in an industrial facility? Take a look at some of the most common reasons:

1. Short circuit fault

- Occurs when there is contact between a neutral and live conductor, causing a current to be drawn that is much higher than the rated value

- In this instance, the magnetic tripping mechanism is activated to clear the fault and prevent a fire or damage to equipment

2. Ground fault

- Occurs when a live conductor touches a conductive surface that is not a part of the circuit

- If the current is extremely high, the fault must be cleared immediately by the magnetic tripping mechanism in the circuit breaker

3. Electrical circuit overload

- Occurs when the current passing through the circuit breaker exceeds its rated value for a duration longer than what’s normal for the application

- It’s also possible for the breaker to trip due to an overload when the disconnection does not occur immediately (e.g. when the thermal mechanism is acting instead of the magnetic one)

4. Selecting the incorrect breaker for the application

- It is imperative to correctly size and select a circuit breaker to ensure it matches the specific application

- For example: If you use a Type B breaker that trips at 3–5 times its rated current for a motor that draws 8 times its rated current when started, it would be impossible for the circuit breaker to start because it would react as if a fault has occurred, and would disconnect the motor immediately

Sizing a Circuit Breaker

To properly calculate the correct circuit breaker size, numerous factors need to be considered. Examples of these include the environment temperature, load type, cable material, and so forth.

For the purpose of illustrating a calculation example, we are simplifying it to the basics and assuming the power factor is 1 (Resistive load).

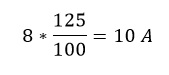

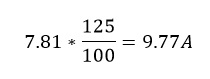

The examples below can be used to size a circuit breaker for both single phase and three phase systems. Note that it has been suggested that the size of the circuit breaker should not be more than 125 % of the current flowing through the circuit.

1. Single Phase Supply

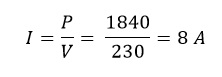

Assuming that it is being powered by a supply of 230V, how do we calculate the correct circuit breaker size for a load of 1840W?

Circuit Current:

The minimum rating of the circuit breaker should be 8 A.

Circuit Breaker Size:

The recommended size of the circuit breaker is 10A.

2. Three Phase Supply

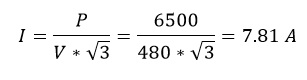

What is the size of the circuit breaker that should be used for a residential 6.5kW, three phase 480V load?

Circuit Current:

Circuit Breaker Size:

The recommended size of the circuit breaker that should be used is 10A.

Sizing a three phase system will vary depending on the type of load i.e., light, motor, inductive or capacitive. Click HERE for more circuit breaker selection tools.

Circuit breakers is a vast subject, and we've just scratched the surface. Have a question about breakers? Or perhaps you need advice on the ranges available? CHAT to us. We’re happy to help!

Want to receive these articles straight to your inbox? SUBSCRIBE to join our mailing list now!